Most industrial design firms favor a development process that involves the creation of various simple, “pretty” renderings of concepts they are pitching to their client. These renderings usually do not represent product visions that fully understand the product’s functional requirements, and they rarely present a vision that expresses the effects that various manufacturing processes may have on the end product. In the end, the renderings that prioritize an idealized aesthetic over a mechanically sound proposal is unlikely to be truthful about the quality and economic cost of realizing the project.

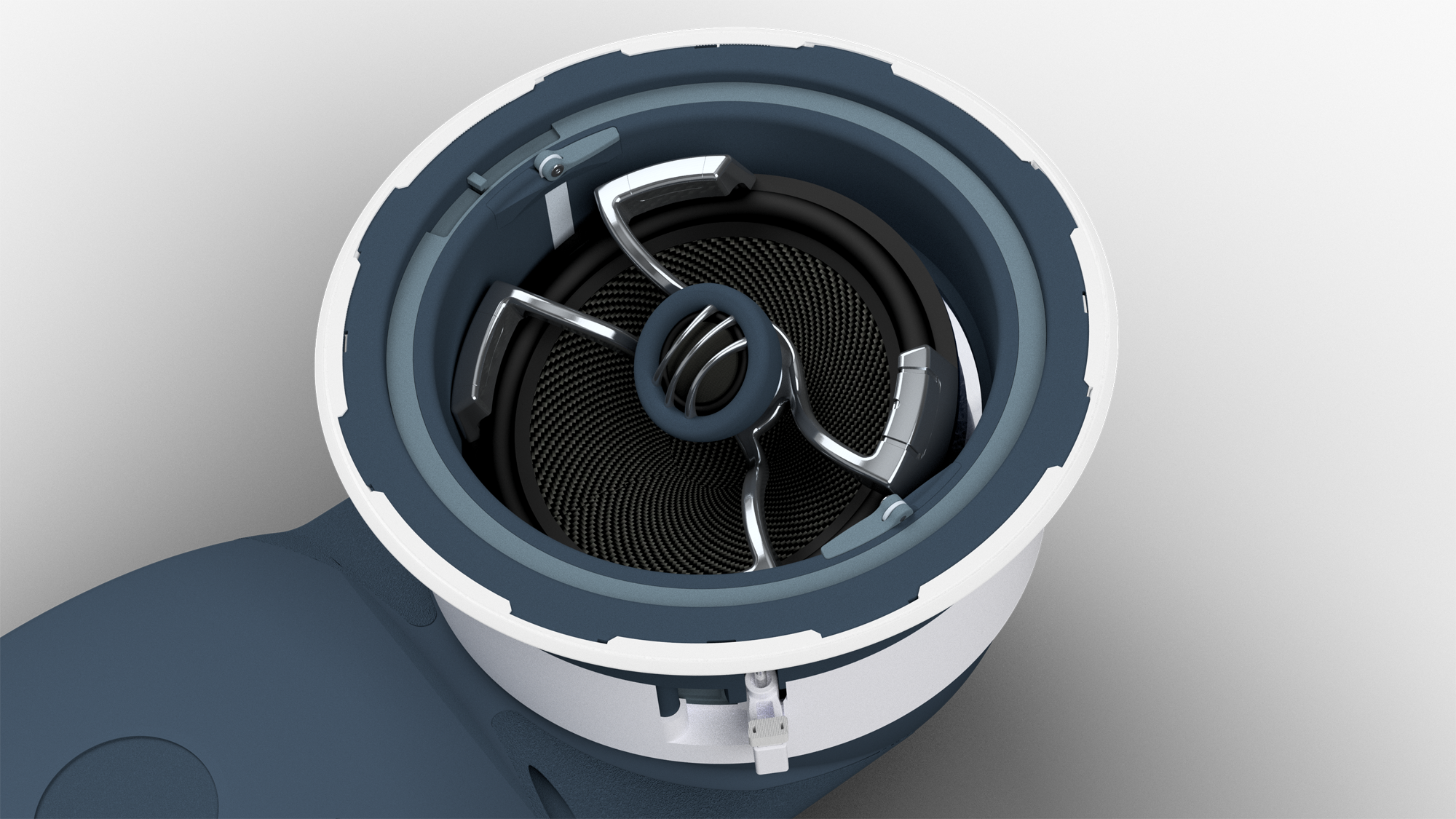

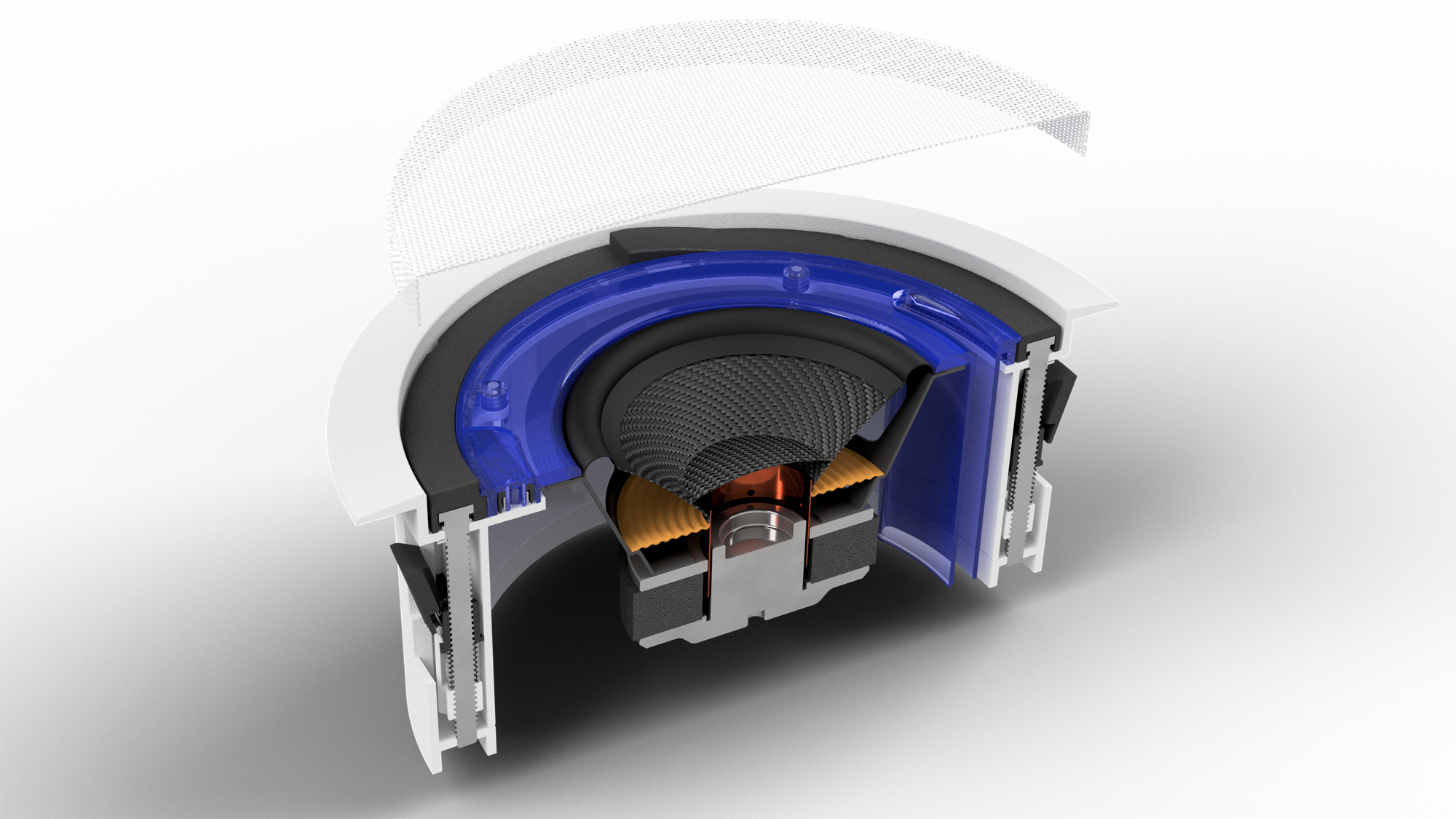

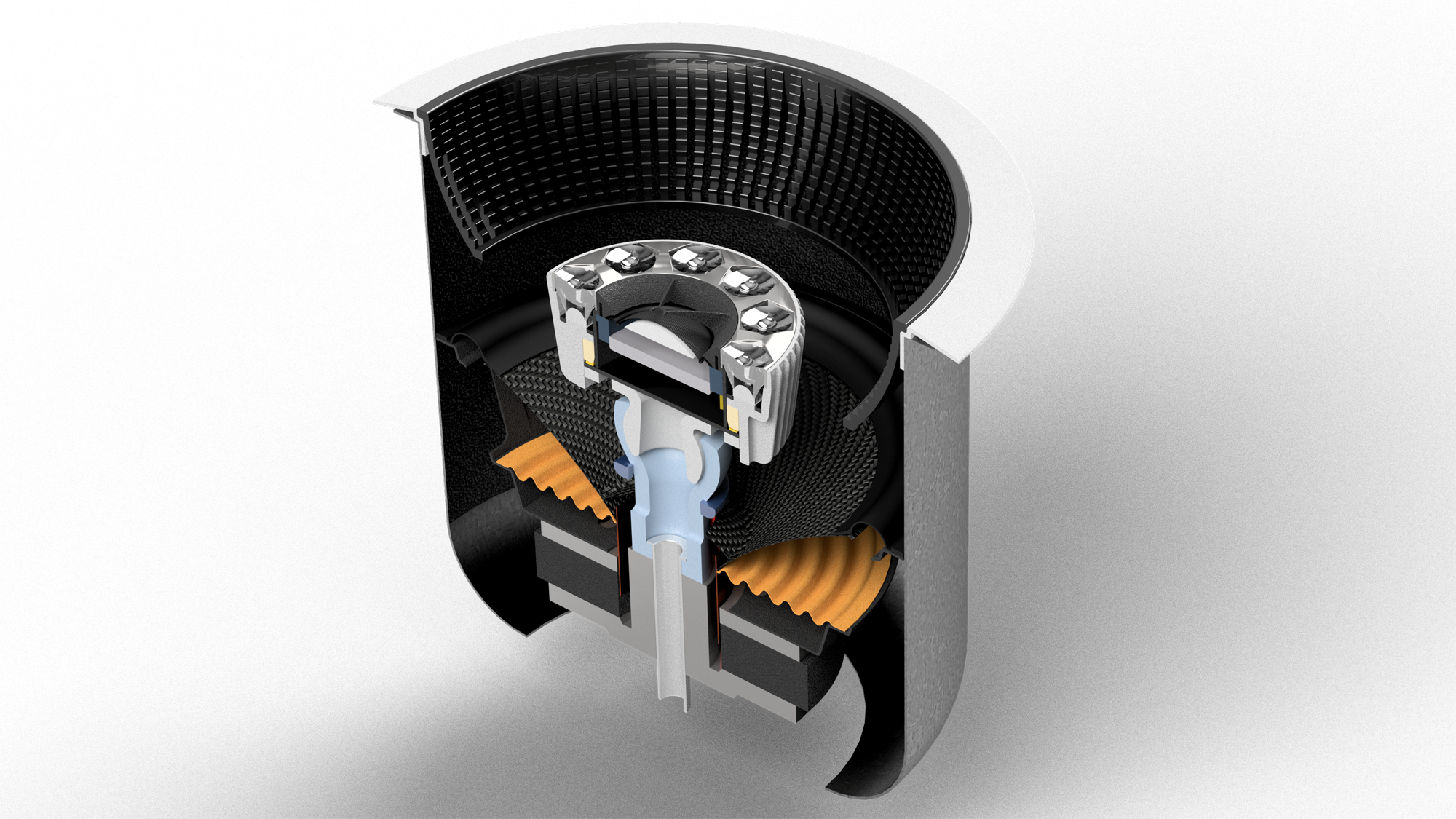

eMagineFactory builds its concept(s) of the client’s product vision directly using parametric solids. We incorporate all the known components and the effects that manufacturing processes might have on the part(s) (like draft angles and parting lines) and the assemblies’ cosmetic and functional requirements right from the start. Creating this database of knowns does take a little more time up front, but it yields big advantages: you will have early testable parts and preliminary bills-of-materials, not to mention the ability to create visually pleasing renderings that are much closer to a final product. This method is avoided by many ID firms because of the perceived complexity of parametric modeling. However, in reality, provided the models are built with modification in mind, it’s often relatively simple to iterate the design until all the stakeholders are satisfied.

eMagineFactory works from the “inside out” instead of from the “outside in”, preferring a process that favors “form following function” versus “function following form”. We believe that this methodology better protects our clients’ budgets, their vision and the integrity of their brand, while still producing great selling products that are aesthetically advanced and award winning.